Laser marking is one of the many industries in which laser technology has transformed. This flexible method goes beyond basic engraving. It provides a range of options to mark, etch, and customize various surfaces with unparalleled accuracy and durability. We explore the potential and multiple applications of laser marking today. Go deeper into this intriguing field.

Understanding the Process:

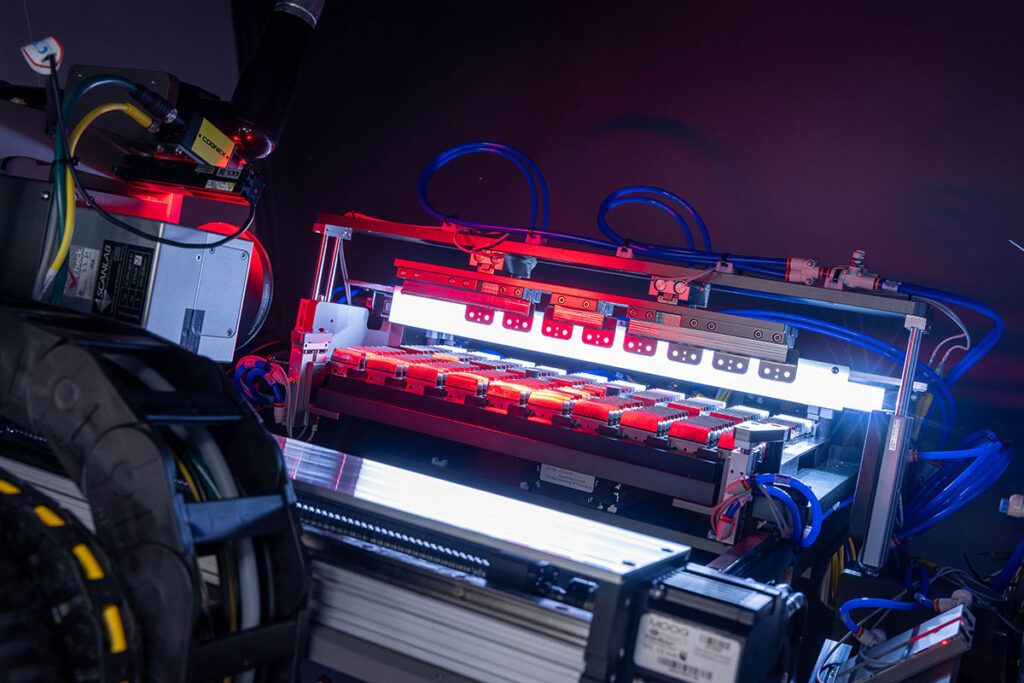

A high-intensity light beam is directed onto a substance to perform laser marking. Depending on the type, power, and characteristics of the substance. This interaction can have different effects. Specific lasers cause photoablation, which vaporizes the material on the surface.

Others set off photothermal reactions, which result in controlled oxidation. Or melting and hue shifts. With careful manipulation, high contrast marks are produced. They guarantee its longevity and readable quality without causing physical harm to the material.

Fundamentally, laser marking modifies a material’s surface characteristics. Without removing it by using a concentrated laser beam to interact with it. Several outcomes may result from this interaction, including:

Ablation:

They are frequently used in engraving applications. Ablation involves removing a small layer of the material to reveal visible depressions.

Discoloration:

It is changing the chemical makeup of a surface without removing material. That results in a color shift (such as blackening on metal surfaces).

Annealing:

It changes the microstructure of metal surfaces to produce a contrasting look by adjusting light reflection.

Foaming:

The laser can foam organic materials. Such as plastics, you are giving them a raised surface texture.

Advantages of Laser Marking:

Laser marking benefits from being non-contact and has several advantages.

Precision:

Lasers can produce micro-text, complex designs. And even QR codes with remarkable detail. Because of their unmatched accuracy.

Permanence:

Laser marks have long-lasting visibility. Due to their high resistance to chemicals, wear and tear, and even extraordinarily high and low temperatures.

Versatility:

A wide range of materials. Including metals, polymers, wood, glass, and even certain textiles. It can be treated using this technology.

Speed:

High-volume industrial applications benefit significantly from the astonishing speeds. At which modern laser systems work.

A Spectrum of Possibilities:

The versatility of laser marking is what makes it so beautiful on a variety of surfaces. Metals that are easily tagged for branding. Serialization and product identification include titanium, steel, and aluminum.

Because the technique is clean and non-contaminating. Plastics like acrylic and ABS are used in electronics and medical devices. For ornamental or practical reasons, complex designs. You can apply it to even the most delicate surfaces, such as glass and ceramics.

Industry-Specific Applications:

There are several industries where laser marking is essential:

Manufacturing:

Quality control, traceability, and product identification are crucial. Accuracy, durability, and tamper-proof markings on components. And final goods are guaranteed by laser marking.

Electronics:

Precise markings are necessary for the identification. And they are tracking small circuits and delicate components. Sensitive components are protected by high-resolution and non-contact processing provided by laser marking.

Medical devices:

In the medical industry, traceability and regulatory compliance are essential. Permanent, sterile, and biocompatible markings can be applied to implants and instruments via laser marking.

Jewelry and customization:

Intricate features and individualized designs can be added. But where: using laser marking in rings, bracelets, and other jewelry pieces. It increases their value and emotional resonance.

Consumer goods:

Laser marking improves product attractiveness and brand identification for everything from customized phone cases to branded gadgets.

Packing:

I am writing batch numbers, expiration dates, and other information straight on the container.

Art & design:

We are producing elaborate and one-of-a-kind works of art. On a variety of surfaces for ornamental purposes.

Textile marking:

Personalized and permanent designs and logos applied to garments and other textile products.

Food and drink:

Clearly label food packaging with details like ingredients and production dates.

The Future of Precision:

We may anticipate even more fascinating developments in laser marking as technology progresses. Increased power, speed, and control will make new materials and applications possible. Furthermore, there is a combination of AI and machine learning. It may result in intelligent marking systems.

That can recognize various materials. Which automatically modifies parameters to achieve the best possible outcomes. The capabilities of laser technology increase as it advances. Researchers are looking into:

Ultrafast lasers:

These lasers can do fine micromachining and delicate marks. Because they provide even more control and quicker processing times.

Multi-color marking:

Using specialist materials or combining separate lasers allows. For the creation of vivid, multi-colored graphics on a variety of surfaces. Get more info there.

Direct-write electronics:

The ability to directly create working electronic circuits on substrates. Using laser marking could lead to flexible and compact electronics.

Conclusion

To sum up, laser marking is a robust and adaptable technology. That provides accuracy, durability, and countless opportunities. Its influence is seen in everything from personalized presents to industrial uses. We may anticipate even more creative and fascinating applications for this incredible instrument. As technology develops, it influences the direction of manufacturing. And customization in a variety of industries.

Welcome to our blog! My name is Yuvraj Kore, and I am a blogger who has been exploring the world of blogging since 2017. It all started back in 2014 when I attended a digital marketing program at college and learned about the intriguing world of blogging.